- Project task As part of a factory planning process, HPMlog has developed a logistics concept for gradual implementation, according to which the interaction of production and […]

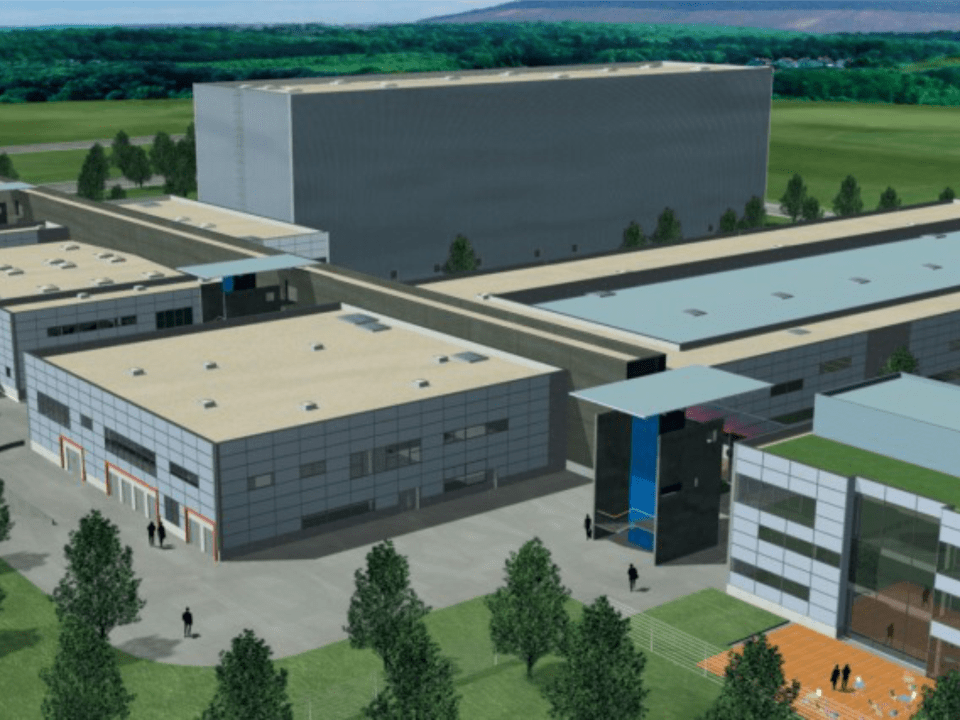

- Project task Concept & Basic Design – As part of a plant expansion for a pharmaceutical company, a new building for production and logistics was to […]

- Project task Plant expansion in pharmaceutical production – Following the integration of an acquired producer of biopharmaceutical products into the Group, a plant expansion is to […]