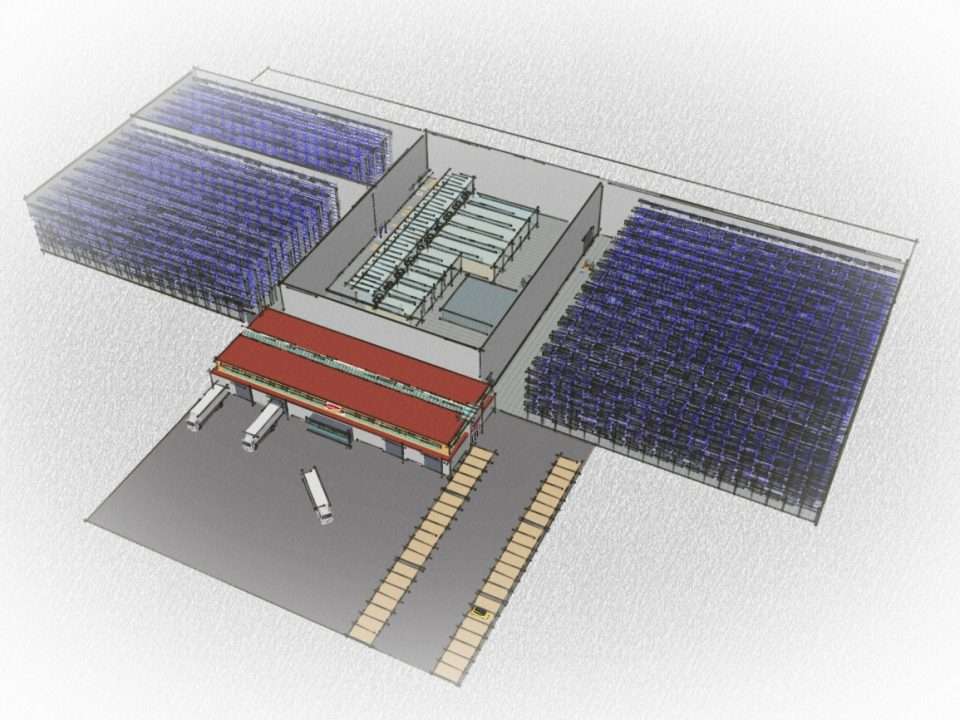

- Project task The global expansion of renewable energies requires a rapid adjustment of production capacities in order to keep pace with the growth of the solar […]

- Project task The electronics retail business is growing rapidly in Eastern Europe. Customers place a lot of value on the latest products and attach great importance […]

- Project task The growth in the product range, branch growth through higher branch density and regional growth demand the expansion of logistics capacity and performance at […]

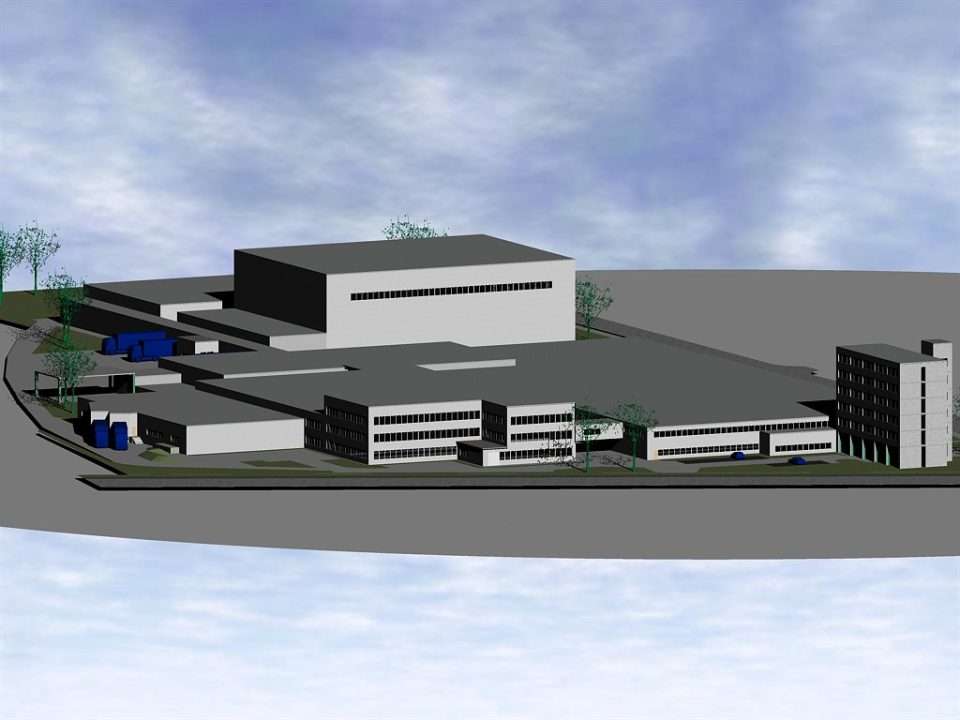

- Project task As part of a factory planning process, HPMlog has developed a logistics concept for gradual implementation, according to which the interaction of production and […]

- Project task As part of the review and optimization of the logistical structures for the supply and disposal of the plant location for the production of […]

- Project task As part of a factory planning process, HPMlog develops a flexible, future-proof logistics concept. The focus of the concept is on the optimal linking […]